To properly setup a pull pull system is not as easy as running cable between the horns and servo wheel. If you are a geometry wiz, then you can set and play with numbers and come up with the ideal setup. You must take into consideration of the width of the connection’s sports on the horn from the center line along with is the spots lines up with the highline or is it offset. This must be looked at both on the control and servo side. If anything is off, you will find one side will go slack when to deflect the surface.

I personally like to go with a setup that you don’t see often. This is using a wheel/pulley on the servo. I started using this setup on my 1/4 cubs back in 2000. With this setup you can throw all the geometry away. As with a pulley as it turns the same amount of cable will be given out from one side as it is taken up on the other. This will make your cables tight all the time.

In the past they made pully wheels for servos, not many are made now. For my Cub on the ailerons, I made my own. I use a servo wheel along with a couple layers of 3/32 ply. I use my dreaml and a mandrel to turn the two parts into a perfect circle. I epoxy them tighter along with the servo wheel and use a couple 2-56 screws to hold it all together.

You will notice a small square chunk out of it. This will need to be just big enough that you wheel collar will pop in. I use the 1/16-wheel collars for what I call the cable lock.

Place your pully on a centered servo so the cable lock will be on the same side as your control surface. You will take one long section of cable that will go from the surface to the servo and back to the surface. Place the cable lock (Wheel collar) in the middle of the cable. Now wrap each end of the cable around the pulley and then back to your surface. Install your clevis setup on the surface and snug up the cable. Do not over tighten your cables.

When you are happy with the servo centered and the surface centered then screw the lock screw in the wheel collar. This will lock the cable and keep it from sliding on the pulley.

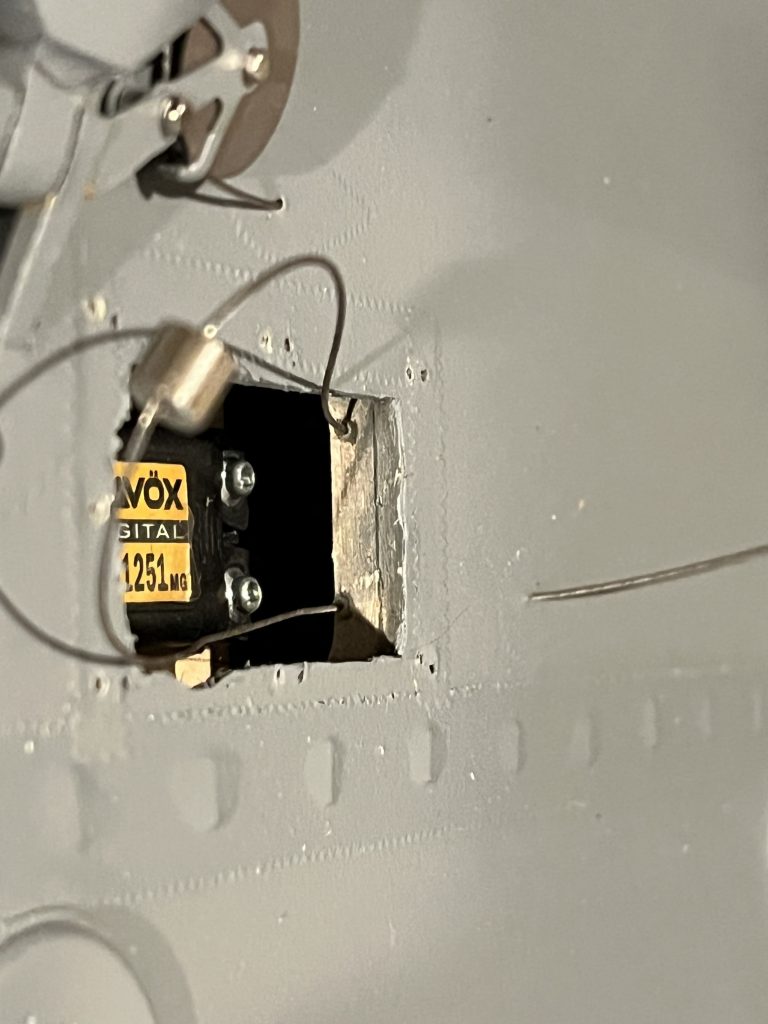

A few photos from the setup of my scale ailerons on the L4

Scale horn on the ailerons. Remember they are true scale so they are hinged on the bottom.